HI-LOK™ and HI-LITE™ Fasteners.

CompositeDescription.

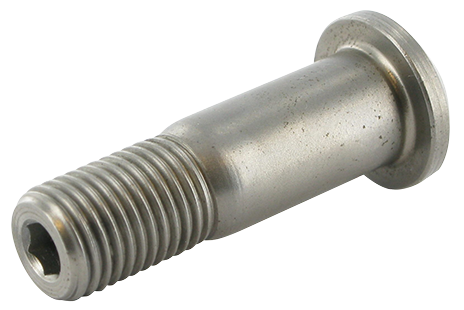

Delivering high strength controlled preloaded system, our pins range offers a versatile solution for most of structural assemblies. The pins are easily installed from one side, by one person, quietly, even is most restricted areas. Discover our range, from our original HI-LOK™ system, to our latest HI-LITE™ pins with an improved recess.

Features.

- Controlled preload

- Wide variety of materials and coatings for installation in all structures

- Made for shear and/or tension applications, on plain or sloped surfaces

- Limited access installation, using conventional tooling

- Suitable for clearance, transition and low interference fit installation

Range.

HI-LITE™ pin (HST)

HI-LITE™ pins are the direct evolution of HI-LOK™ pins. These fasteners can be used for clearance, or low interference fit throughout aircraft, from wings to fuselage, in engine fairings, and more. Combined with HI-LITE™ nuts and collars, they provide up to 13% weight saving compared to the previous HI-LOK™ generation.

HI-LITE™ pin with ASTER™ recess (HSTR)

The HSTR™ family is latest innovation of our pins range. It offers all the benefits of the HI-LITE™ pins with an improved recess that prevents failure during the assembly process. This product is especially suited for clearance fit assemblies of composite structures.

This feature is also available for HI-LOK™ pin users, with our HLR™ pins.

HI-LOK™ pin (HL)

The HI-LOK™ pins are the original solution for strong and reliable assemblies. Having a wide range of shapes, materials and coatings, they are suited for most of structural assemblies. This solution is still commonly used in the aerospace industry, but can be safely replaced by equivalent HI-LITE™ pins for improved weight saving. The latest HLR™ range also comes with an improved ASTER™ recess, especially suited for clearance fit assemblies of composite structures.

HI-TIGUE™ pin (HLT)

The HI-TIGUE™ system has been the first practical interference fit fastening system to be developed. It provides improved fatigue benefits by combining the hole-improvement qualities of the HI-TIGUE™ pin and the consistent preloading qualities of the HI-LOK™ collar.

Licensed manufacturers.

In order to provide the best quality for our products, HI-LITE™ and HI-LOK™ pins are only manufactured by licensed suppliers. A supplier list can be found here:

HST™ pins configurator.

Contact R&D

Regulars drawings

| Material | Head Style | Thread Type | Tensile Strength (Ksi) | Shear Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 160 | 95 |

HST10 |

HST110 | HST410 |

| 6AL-4V Titanium | 100° flush Shear | UNJ | 160 | 95 |

HST11 |

HST111 | HST411 | |

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 |

HST12 |

HST112 | HST412 |

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HST13 |

HST113 | HST413 | |

| 6AL-4V Titanium | Self-aligning Tension | UNJ | 160 | 95 |

HST536 |

HST636 | HST736 | |

| Alloy Steel | Protruding Shear |

|

UNJ | 160 | 95 |

HST18 |

HST118 | HST218 |

| Alloy Steel | 100° flush Shear | UNJ | 160 | 95 |

HST19 |

HST119 | HST219 | |

| Alloy Steel | Protruding Tension |

|

UNJ | 160 | 95 |

HST20 |

HST120 | HST220 |

| Alloy Steel | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HST21 |

HST121 | HST221 | |

| A-286 | Protruding Shear |

|

UNJ | 160 | 95 |

HST40 |

HST140 | HST240 |

| A-286 | 100° flush Shear | UNJ | 160 | 95 |

HST41 |

HST141 | HST241 | |

| A-286 | Protruding Tension |

|

UNJ | 160 | 95 |

HST48 |

HST248 | HST748 |

| A-286 | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HST49 |

HST249 | HST749 | |

| INCONEL® 718 | Protruding Shear |

|

UNJ | 210 | 125 |

HST52 |

HST152 | HST252 |

| INCONEL® 718 | Protruding Tension |

|

UNJ | 210 | 125 |

HST54 |

HST154 | HST254 |

| INCONEL® 718 | 100° flush Shear | UNJ | 210 | 125 |

HST57 |

HST157 | HST257 | |

| INCONEL® 718 | 100° MS24694 flush Tension | UNJ | 210 | 125 |

HST59 |

HST159 | HST259 | |

| PH13-8MO Stainless Steel | Protruding Shear |

|

UNJ | 210 | 125 |

HST644 |

HST744 | HST844 |

| PH13-8MO Stainless Steel | 100° flush Shear | UNJ | 210 | 125 |

HST645 |

HST745 | HST845 | |

| PH13-8MO Stainless Steel | Protruding Tension |

|

UNJ | 210 | 125 |

HST646 |

||

| PH13-8MO Stainless Steel | 100° MS24694 flush Tension | UNJ | 210 | 125 |

HST647 |

|||

Customs drawings

| Material | Head Style | Thread Type | Tensile Strength (Ksi) | Shear Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|

| 7075-T6 Aluminum | Protruding Shear |

|

UNJ | HST22 | HST122 | HST222 | ||

| 7075-T6 Aluminum | 100° MS20426 flush Shear | UNJ | HST23 | HST123 | HST223 | |||

| INCONEL® 718 | 100° flush crown Shear | UNJ | 210 | 125 | HST25 | |||

| 7075-T6 Aluminum | 100° MS24694 flush Tension | UNJ | HST29 | |||||

| 6AL-4V Titanium | 100° flush crown Shear | UNJ | 160 | 95 | HST35 | |||

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 160 | 95 | HST108 | ||

| 6AL-4V Titanium | 100° flush Shear | UNJ | 160 | 95 | HST109 | |||

| Alloy Steel | Protruding Shear |

|

UNJ | 180 | 108 | HST134 | ||

| Alloy Steel | 100° flush crown Shear | UNJ | 180 | 108 | HST135 | |||

| INCONEL® 718 | Protruding Tension |

|

UNJ | 210 | 125 | HST144 | ||

| 6AL-4V Titanium | 130° flush Shear | UNJ | 160 | 95 | HST305 | HST415 | HST515 | |

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 160 | 95 | HST310 | ||

| Alloy Steel | 130° flush crown Shear | UNJ | 160 | 95 | HST311 | |||

| 6AL-4V Titanium | 130° flush crown Shear | UNJ | 160 | 95 | HST315 | HST415 | HST515 | |

| A-286 | 130° flush Shear | UNJ | 160 | 95 | HST317 | |||

| 6AL-4V Titanium | 130° flush recess Shear | UNJ | 160 | 95 | HST325 | |||

| 6AL-4V Titanium | 130° flush crown Shear | UNJ | 160 | 95 | HST327 | |||

| 6AL-4V Titanium | 100° MS20426 flush Shear | UNJ | 160 | 95 | HST523 | |||

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 | HST533 | HST633 | HST733 | |

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HST622 | HST632 | |

| Alloy Steel | 100° flush Shear | UNJ | 160 | 95 | HST651 | |||

| Alloy Steel | Protruding Tension |

|

UNJ | 180 | 108 | HST720 | HST764 | HST820 |

| 6AL-4V Titanium | 100° flush special Shear | UNJ | 160 | 95 | HST755 | HST855 | HST859 | |

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HST756 | HST856 | HST860 |

| A-286 | 100° flush special Shear | UNJ | 160 | 95 | HST757 | |||

| INCONEL® 718 | 100° flush special Shear | UNJ | 210 | 125 | HST765 | HST767 | HST769 | |

| Alloy Steel | 100° flush special Shear | UNJ | 180 | 108 | HST803 | HST823 | HST833 | |

| 6AL-4V Titanium annealed | 100° flush special Shear | UNJ | HST955 | HST957 | HST959 | |||

| 6AL-4V Titanium annealed | Protruding Tension |

|

UNJ | HST956 | HST958 | HST960 | ||

| 6AL-4V Titanium | Protruding Shear |

|

M | 160 | 95 | HSTM10 | HSTM310 | |

| 6AL-4V Titanium | 100° flush Shear | M | 160 | 95 | HSTM11 | HSTM311 | ||

| 6AL-4V Titanium | Protruding Tension |

|

M | 160 | 95 | HSTM12 | HSTM312 | HSTM612 |

| 6AL-4V Titanium | 100° flush Tension | M | 160 | 95 | HSTM13 | HSTM313 | HSTM613 | |

| Alloy Steel | Protruding Shear |

|

M | 160 | 95 | HSTM18 | ||

| Alloy Steel | 100° flush Shear | M | 160 | 95 | HSTM19 | |||

| Alloy Steel | Protruding Tension |

|

M | 160 | 95 | HSTM20 | ||

| Alloy Steel | 100° flush Tension | M | 160 | 95 | HSTM21 | |||

| 7075-T6 Aluminum | Protruding Shear |

|

M | HSTM22 | ||||

| 7075-T6 Aluminum | 100° flush Shear | M | HSTM23 | |||||

| INCONEL® 718 | Protruding Tension |

|

M | 180 | 108 | HSTM32 | ||

| PH13-8MO Stainless Steel | 100° flush Shear | M | 210 | 125 | HSTM35 | |||

| PH13-8MO Stainless Steel | Protruding Tension |

|

M | 210 | 125 | HSTM36 | ||

| A-286 | Protruding Shear |

|

M | 160 | 95 | HSTM40 | ||

| A-286 | 100° flush Shear | M | 160 | 95 | HSTM41 | |||

| A-286 | Protruding Tension |

|

M | 160 | 95 | HSTM48 | ||

| A-286 | 100° flush Tension | M | 160 | 95 | HSTM49 | |||

| INCONEL® 718 | Protruding Shear |

|

M | 210 | 125 | HSTM52 | ||

| 6AL-4V Titanium | 100° flush special Shear | M | 160 | 95 | HSTM755 | |||

| 6AL-4V Titanium | Protruding Shear |

|

MJ | 160 | 95 | HSTMJ10 | ||

| 6AL-4V Titanium | 100° flush Shear | MJ | 160 | 95 | HSTMJ11 | |||

| 6AL-4V Titanium | Protruding Tension |

|

MJ | 160 | 95 | HSTMJ12 | ||

| 6AL-4V Titanium | 100° flush Tension | MJ | 160 | 95 | HSTMJ13 | |||

| INCONEL® 718 | Protruding Tension |

|

MJ | 180 | 108 | HSTMJ32 | ||

| A-286 | Protruding Tension |

|

MJ | 210 | 125 | HSTMJ48 | ||

| A-286 | 100° flush Tension | MJ | 210 | 125 | HSTMJ49 | |||

| WASPALOY® | 130° flush Shear | MJ | 160 | 95 | HSTMJ57 | |||

| 6AL-4V Titanium | 130° flush crown Shear | MJ | 160 | 95 | HSTMJ315 | |||

| 6AL-4V Titanium | Protruding Shear |

|

MJ | 160 | 95 | HSTMJ318 | ||

| 6AL-4V Titanium | Protruding reduced Shear |

|

MJ | 160 | 95 | HSTMJ319 | ||

| A-286 | Protruding Shear |

|

MJ | 160 | 95 | HSTMJ320 | ||

| INCONEL® 718 | Protruding Shear |

|

MJ | 180 | 108 | HSTMJ322 | ||

| INCONEL® 718 | Protruding Shear |

|

MJ | 210 | 125 | HSTMJ420 | ||

| INCONEL® 718 | 100° flush Shear | MJ | 210 | 125 | HSTMJ421 | |||

| INCONEL® 718 | Protruding Tension |

|

MJ | 210 | 125 | HSTMJ422 | ||

| INCONEL® 718 | 100° flush Tension | MJ | 210 | 125 | HSTMJ423 | |||

| 6AL-4V Titanium | Protruding special Shear |

|

MJ | 160 | 95 | HSTMJ510 | ||

| A-286 | Protruding Shear |

|

MJ | 160 | 95 | HSTMJ520 | ||

| 6AL-4V Titanium | 100° flush crown Shear | UNJ | 95 | HST331 | ||||

HSTR™ pins configurator.

Contact R&D

Regulars drawings

| Material | Head Style | Thread Type | Shear Strength (Ksi) | Tensile Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | 160 |

HSTR10 |

HSTR110 | HSTR410 |

| 6AL-4V Titanium | 100° flush Shear | UNJ | 95 | 160 |

HSTR11 |

HSTR111 | HSTR411 | |

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 95 | 160 |

HSTR12 |

HSTR112 | HSTR412 |

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 95 | 160 |

HSTR13 |

HSTR113 | HSTR413 | |

| 6AL-4V Titanium | 130° flush crown shear | UNJ | 95 | 160 |

HSTR315 |

HSTR415 | HSTR515 | |

HLR™ pins configurator.

Contact R&D

Regulars drawings

| Material | Head Style | Thread Type | Shear Strength (Ksi) | Tensile Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | 160 | HLR10 | HLR110 | HLR410 |

| 6AL-4V Titanium | 100° flush Shear | UNJ | 95 | 160 | HLR11 | HLR111 | HLR411 | |

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 95 | 160 | HLR1012 | HLR1022 | HLR1032 |

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 95 | 160 | HLR1013 | HLR1023 | HLR1033 | |

| 6AL-4V Titanium | 100° MS20426 flush Shear | UNJ | 95 | 160 | HLR523 | HLR537 | HLR823 | |

HL™ pins configurator.

Contact R&D

Regulars drawings

| Material | Head Style | Thread Type | Tensile Strength (Ksi) | Shear Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | 3rd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|---|

| 6Al-4V Titanium | Protruding Shear |

|

UNJ | 160 | 95 |

HL10 |

HL110 | HL410 | |

| 6Al-4V Titanium | 100° flush Shear | UNJ | 160 | 95 |

HL11 |

HL111 | HL411 | ||

| 6Al-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 |

HL12 |

HL112 | HL412 | |

| 6Al-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HL13 |

HL113 | HL413 | ||

| Alloy Steel | Protruding Shear |

|

UNJ | 160 | 95 |

HL18 |

HL62 | HL218 | HL202 |

| Alloy Steel | 100° flush Shear | UNJ | 160 | 95 |

HL19 |

HL63 | HL219 | HL203 | |

| Alloy Steel | Protruding Tension |

|

UNJ | 160 | 95 |

HL20 |

HL64 | HL220 | HL204 |

| Alloy Steel | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HL21 |

HL65 | HL221 | HL205 | |

| A-286 | Protruding Shear |

|

UNJ | 160 | 95 |

HL40 |

HL140 | HL240 | HL702 |

| A-286 | 100° flush Shear | UNJ | 160 | 95 |

HL41 |

HL141 | HL241 | HL1203 | |

| A-286 | Protruding Tension |

|

UNJ | 160 | 95 |

HL48 |

HL248 | HL748 | HL706 |

| A-286 | 100° MS24694 flush Tension | UNJ | 160 | 95 |

HL49 |

HL249 | HL749 | HL1205 | |

| PH13-8MO Stainless Steel | Protruding Shear |

|

UNJ | 220 | 125 |

HL644 |

HL744 | HL844 | |

| PH13-8MO Stainless Steel | 100° flush Shear | UNJ | 220 | 125 |

HL645 |

HL751 | HL851 | ||

| PH13-8MO Stainless Steel | Protruding Tension |

|

UNJ | 220 | 125 |

HL646 |

HL746 | HL846 | |

| PH13-8MO Stainless Steel | 100° MS24694 flush Tension | UNJ | 220 | 125 |

HL647 |

HL753 | HL853 | ||

| INCONEL® 718 | 100° flush Shear | UNJ | 220 | 125 | HL701 | HL937 | HL947 | ||

| INCONEL® 718 | Protruding Tension |

|

UNJ | 210 | 125 | HL730 | HL938 | HL948 | |

| INCONEL® 718 | 100° MS24694 flush Tension | UNJ | 210 | 125 | HL731 | HL939 | HL949 | ||

| INCONEL® 718 | Protruding Shear |

|

UNJ | 220 | 125 | HL754 | HL936 | HL946 | |

Customs drawings

| Material | Head Style | Thread Type | Tensile Strength (Ksi) | Shear Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | 3rd Oversize Shank | |

|---|---|---|---|---|---|---|---|---|---|

| 7075-T6 Aluminum | Protruding Shear |

|

UNJ | HL22 | HL122 | HL258 | |||

| 7075-T6 Aluminum | 100° MS20426 flush Shear | UNJ | HL23 | HL123 | HL259 | ||||

| 7075-T6 Aluminum | 100° MS24694 flush Tension | UNJ | HL29 | HL129 | |||||

| 431 Stainless Steel | Protruding Shear |

|

UNJ | 220 | 125 | HL30 | HL66 | HL58 | |

| 431 Stainless Steel | 100° flush Shear | UNJ | 220 | 125 | HL31 | HL67 | HL59 | ||

| 431 Stainless Steel | Protruding Tension |

|

UNJ | 220 | 125 | HL32 | HL36 | HL136 | |

| 431 Stainless Steel | 100° MS24694 flush Tension | UNJ | 220 | 125 | HL33 | HL37 | HL137 | ||

| 300 series Stainless Steel | 100° flush Shear | UNJ | HL43 | ||||||

| 431 Stainless Steel | Protruding Shear |

|

UNJ | 220 | 125 | HL54 | HL52 | HL458 | |

| 431 Stainless Steel | 100° flush Shear | UNJ | 220 | 125 | HL61 | HL53 | HL459 | ||

| 431 Stainless Steel | 100° MS20426 flush Shear | UNJ | 220 | 125 | HL109 | ||||

| 6Al-4V Titanium | Self-aligning Tension | UNJ | 160 | 95 | HL128 | ||||

| PH15-7MO Stainless Steel | Protruding Shear |

|

UNJ | 220 | 125 | HL150 | |||

| PH15-7MO Stainless Steel | 100° flush Shear | UNJ | 220 | 125 | HL151 | ||||

| PH15-7MO Stainless Steel | Protruding Tension |

|

UNJ | 220 | 125 | HL152 | |||

| PH15-7MO Stainless Steel | 100° MS24694 flush Tension | UNJ | 220 | 125 | HL153 | ||||

| MP35N | Protruding Shear |

|

UNJ | 260 | 132 | HL156 | |||

| MP35N | 100° flush Shear | UNJ | 260 | 132 | HL157 | ||||

| MP35N | Protruding Tension |

|

UNJ | 260 | 132 | HL158 | HL1158 | HL1258 | |

| MP35N | 100° MS24694 flush Tension | UNJ | 260 | 132 | HL159 | HL1159 | HL1259 | ||

| Alloy Steel | 100° flush crown Shear | UNJ | 160 | 95 | HL200 | ||||

| WASPALOY® | Protruding Tension |

|

UNJ | 160 | 95 | HL244 | |||

| PH13-8MO Stainless Steel | Protruding Shear |

|

UNJ | 220 | 125 | HL330 | |||

| 431 Stainless Steel | 100° flush crown Shear | UNJ | 220 | 125 | HL369 | ||||

| A-286 | Protruding Shear |

|

UNJ | 160 | 95 | HL440 | HL442 | HL240 | HL702 |

| A-286 | 100° flush Shear | UNJ | 160 | 95 | HL441 | HL443 | HL241 | HL1203 | |

| A-286 | 100° MS20426 flush Shear | UNJ | 160 | 95 | HL445 | HL447 | HL257 | ||

| A-286 | Protruding Tension |

|

UNJ | 160 | 95 | HL448 | HL452 | HL454 | HL706 |

| A-286 | 100° MS24694 flush Tension | UNJ | 160 | 95 | HL449 | HL453 | HL455 | ||

| 6Al-4V Titanium | Protruding Shear |

|

UNJ | 160 | 95 | HL510 | |||

| 6Al-4V Titanium | 100° flush Shear | UNJ | 160 | 95 | HL511 | ||||

| 6Al-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HL512 | |||

| 6Al-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 | HL513 | ||||

| 6Al-4V Titanium | 100° MS20426 flush Shear | UNJ | 160 | 95 | HL523 | HL537 | HL823 | ||

| Alloy Steel | 100° MS20426 flush Shear | UNJ | 160 | 95 | HL525 | HL527 | HL255 | HL207 | |

| INCONEL® 718 | 100° flush Shear | UNJ | 180 | 108 | HL657 | ||||

| INCONEL® 718 | Protruding Shear |

|

UNJ | 180 | 108 | HL658 | |||

| INCONEL® 718 | 100° MS24694 flush Tension | UNJ | 180 | 108 | HL661 | ||||

| Alloy Steel | Protruding Tension |

|

UNJ | 180 | 108 | HL720 | HL764 | HL820 | |

| Alloy Steel | 100° MS24694 flush Tension | UNJ | 180 | 108 | HL721 | HL765 | HL821 | ||

| 6Al-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HL756 | HL856 | ||

| MP35N | Protruding Tension |

|

UNJ | 260 | 135 | HL1034 | |||

| Alloy Steel | Protruding Tension |

|

UNJ | 160 | 95 | HL1050 | HL1052 | HL1054 | HL1056 |

| Alloy Steel | 100° MS24694 flush Tension | UNJ | 160 | 95 | HL1051 | HL1053 | HL1057 | HL1059 | |

| A-286 | 100° MS24694 flush Tension | UNJ | 160 | 95 | HL1061 | HL1063 | HL1065 | HL1067 | |

| 6AL-4V Titanium | Protruding Shear |

|

M | 160 | 95 | HLM10 | HLM310 | HLM610 | |

| 6AL-4V Titanium | 100° flush Shear | M | 160 | 95 | HLM11 | HLM311 | HLM611 | ||

| 6AL-4V Titanium | Protruding Tension |

|

M | 160 | 95 | HLM12 | HLM312 | HLM612 | |

| 6AL-4V Titanium | 100° flush Tension | M | 160 | 95 | HLM13 | HLM313 | HLM613 | ||

| Alloy Steel | Protruding Shear |

|

M | 160 | 95 | HLM18 | |||

| Alloy Steel | 100° flush Shear | M | 160 | 95 | HLM19 | ||||

| Alloy Steel | Protruding Tension |

|

M | 160 | 95 | HLM20 | HLM320 | HLM620 | |

| Alloy Steel | 100° flush Tension | M | 160 | 95 | HLM21 | HLM321 | HLM621 | ||

| INCONEL® 718 | Protruding Tension |

|

M | 180 | 108 | HLM32 | |||

| PH13-8MO Stainless Steel | Protruding Shear |

|

M | 220 | 125 | HLM34 | |||

| PH13-8MO Stainless Steel | 100° flush Shear | M | 220 | 125 | HLM35 | HLM335 | |||

| PH13-8MO Stainless Steel | Protruding Tension |

|

M | 220 | 125 | HLM36 | HLM336 | HLM636 | |

| PH13-8MO Stainless Steel | 100° flush Tension | M | 220 | 125 | HLM37 | HLM337 | HLM637 | ||

| A-286 | Protruding Shear |

|

M | 160 | 95 | HLM40 | |||

| A-286 | 100° flush Shear | M | 160 | 95 | HLM41 | HLM341 | HLM641 | ||

| A-286 | Protruding Tension |

|

M | 160 | 95 | HLM48 | HLM348 | ||

| A-286 | 100° flush Tension | M | 160 | 95 | HLM49 | ||||

| 6AL-6V-2Sn Titanium | Protruding Shear |

|

M | 180 | 108 | HLM910 | HLM902 | HLM906 | |

| 6AL-6V-2Sn Titanium | 100° flush Shear | M | 180 | 108 | HLM911 | HLM903 | HLM907 | ||

| 6AL-6V-2Sn Titanium | Protruding Tension |

|

M | 180 | 108 | HLM912 | HLM904 | HLM908 | |

| 6AL-6V-2Sn Titanium | 100° flush Tension | M | 180 | 108 | HLM913 | HLM905 | HLM909 | ||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HL1012 | HL1022 | HL1032 | |

| 6AL-4V Titanium | 100° MS20426 flush Shear | UNJ | 160 | 95 | HL145 | HL245 | HL345 | ||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HL1320 | |||

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 | HL1013 | HL1023 | HL1033 | ||

HLT™ pins configurator.

Contact R&D

Customs drawings

| Material | Head Style | Thread Type | Tensile Strength (Ksi) | Shear Strength (Ksi) | Nominal | 1st Oversize Shank | 2nd Oversize Shank | 3rd Oversize Shank | Item Type | |

|---|---|---|---|---|---|---|---|---|---|---|

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | HLT10 | HLT110 | HLT210 | |||

| 6AL-4V Titanium | 100° flush crown Shear | UNJ | 95 | HLT11 | HLT111 | HLT211 | ||||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 160 | 95 | HLT12 | HLT112 | HLT212 | ||

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 160 | 95 | HLT13 | HLT113 | HLT213 | |||

| Alloy Steel | Protruding Shear |

|

UNJ | 160 | 95 | HLT18 | ||||

| Alloy Steel | 100° flush crown Shear | UNJ | 160 | 95 | HLT19 | |||||

| Alloy Steel | Protruding Tension |

|

UNJ | 160 | 95 | HLT20 | ||||

| Alloy Steel | 100° MS24694 flush Tension | UNJ | 160 | 95 | HLT21 | HLT121 | ||||

| 431 Stainless Steel | Protruding Shear |

|

UNJ | 125 | HLT30 | HLT130 | ||||

| 431 Stainless Steel | 100° flush Shear | UNJ | 125 | HLT31 | ||||||

| PH13-8MO Stainless Steel | 100° MS24694 flush crown Tension | UNJ | 125 | HLT33 | ||||||

| A-286 | Protruding Shear |

|

UNJ | 95 | HLT40 | HLT140 | HLT240 | |||

| A-286 | 100° flush Shear | UNJ | 95 | HLT41 | HLT141 | HLT241 | ||||

| A-286 | Protruding Tension |

|

UNJ | 95 | HLT42 | HLT142 | HLT242 | |||

| A-286 | 100° MS24694 flush Tension | UNJ | 95 | HLT43 | HLT143 | HLT243 | ||||

| PH13-8MO Stainless Steel | Protruding Shear |

|

UNJ | 125 | HLT50 | HLT150 | HLT250 | |||

| PH13-8MO Stainless Steel | 100° flush Shear | UNJ | 125 | HLT51 | HLT151 | HLT251 | ||||

| PH13-8MO Stainless Steel | Protruding Tension |

|

UNJ | 125 | HLT52 | HLT152 | HLT252 | |||

| PH13-8MO Stainless Steel | 100° MS24694 flush Tension | UNJ | 125 | HLT53 | HLT153 | HLT253 | ||||

| Alloy Steel | Protruding Shear |

|

UNJ | 180 | 108 | HLT114 | HLT122 | HLT126 | ||

| Alloy Steel | 100° flush crown Shear | UNJ | 180 | 108 | HLT115 | HLT123 | HLT127 | |||

| Alloy Steel | Protruding Special |

|

UNJ | 180 | HLT116 | HLT124 | HLT128 | |||

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | HLT310 | HLT610 | HLT710 | |||

| 6AL-4V Titanium | 100° flush crown Shear | UNJ | 95 | HLT311 | HLT435 | HLT635 | ||||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 95 | HLT312 | HLT612 | HLT712 | |||

| 6AL-4V Titanium | 100° MS24694 flush crown Tension | UNJ | 160 | 95 | HLT313 | HLT437 | HLT637 | |||

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | HLT334 | HLT434 | HLT634 | |||

| 6AL-4V Titanium | 100° flush Shear | UNJ | 95 | HLT335 | HLT435 | HLT635 | ||||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 95 | HLT336 | HLT436 | HLT636 | |||

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 95 | HLT337 | HLT437 | HLT637 | ||||

| INCONEL® 718 | Protruding Shear |

|

UNJ | 210 | 125 | HLT420 | HLT620 | HLT714 | ||

| INCONEL® 718 | 100° flush Shear | UNJ | 210 | 125 | HLT421 | HLT621 | HLT715 | |||

| INCONEL® 718 | Protruding Tension |

|

UNJ | 210 | 125 | HLT422 | HLT622 | HLT716 | ||

| INCONEL® 718 | 100° MS24694 flush Tension | UNJ | 210 | 125 | HLT423 | HLT623 | HLT717 | |||

| 6AL-4V Titanium | Protruding Shear |

|

UNJ | 95 | HLT450 | HLT434 | HLT634 | |||

| 6AL-4V Titanium | 100° flush Shear | UNJ | 95 | HLT451 | HLT435 | HLT635 | ||||

| 6AL-4V Titanium | Protruding Tension |

|

UNJ | 95 | HLT452 | HLT436 | HLT636 | |||

| 6AL-4V Titanium | 100° MS24694 flush Tension | UNJ | 95 | HLT453 | HLT437 | HLT637 | ||||

| 6AL-4V Titanium | 100° flush Shear | UNJ | 160 | 95 | HLT341 | HLT441 | HLT641 | |||

HI-LOK, HI-LITE, HI-TIGUE, HL, HST, HLT, HSTR and HLR are trademarks of HI-SHEAR Corporation, subsidiary of LISI AEROSPACE