Fasteners.

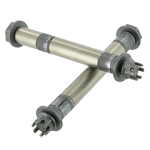

We are one of the 3 world leaders in the field of aeronautical fasteners. We have built our reputation on 70 years of experience working in collaboration with Airbus, Boeing, EMBRAER, Bombardier, ROLLS ROYCE, UTC, SNECMA, GEAE, etc. Our wide range of products enables us to meet all our customers’ needs at the best cost. These products range from standard pin products to more elaborate components, notably lockbolts and turbine cylinders.

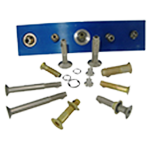

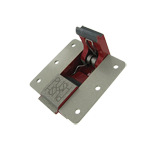

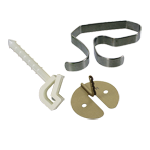

Our product line covers standard and specific aeronautic fastener solutions, locking solutions like latches and expandable bolts, as well as a broad array of interior fasteners. If needed, we also develop and supply the associated tools.

Our innovation ensures our products evolve to meet the changing constraints of the aerospace industry: assembly cycles, conductivity of composite structures and installation noise are some of the challenges we work to overcome by improving our products.

Licensed Manufacturers See our licensed manufacturers

refine by a category

Racing Fasteners technologies Tooling & Temporary Fasteners Safety locking Panel Fasteners Interior fasteners Nuts, collars & inserts Pins, bolts & studs Blind Fastenersrefine by a product type